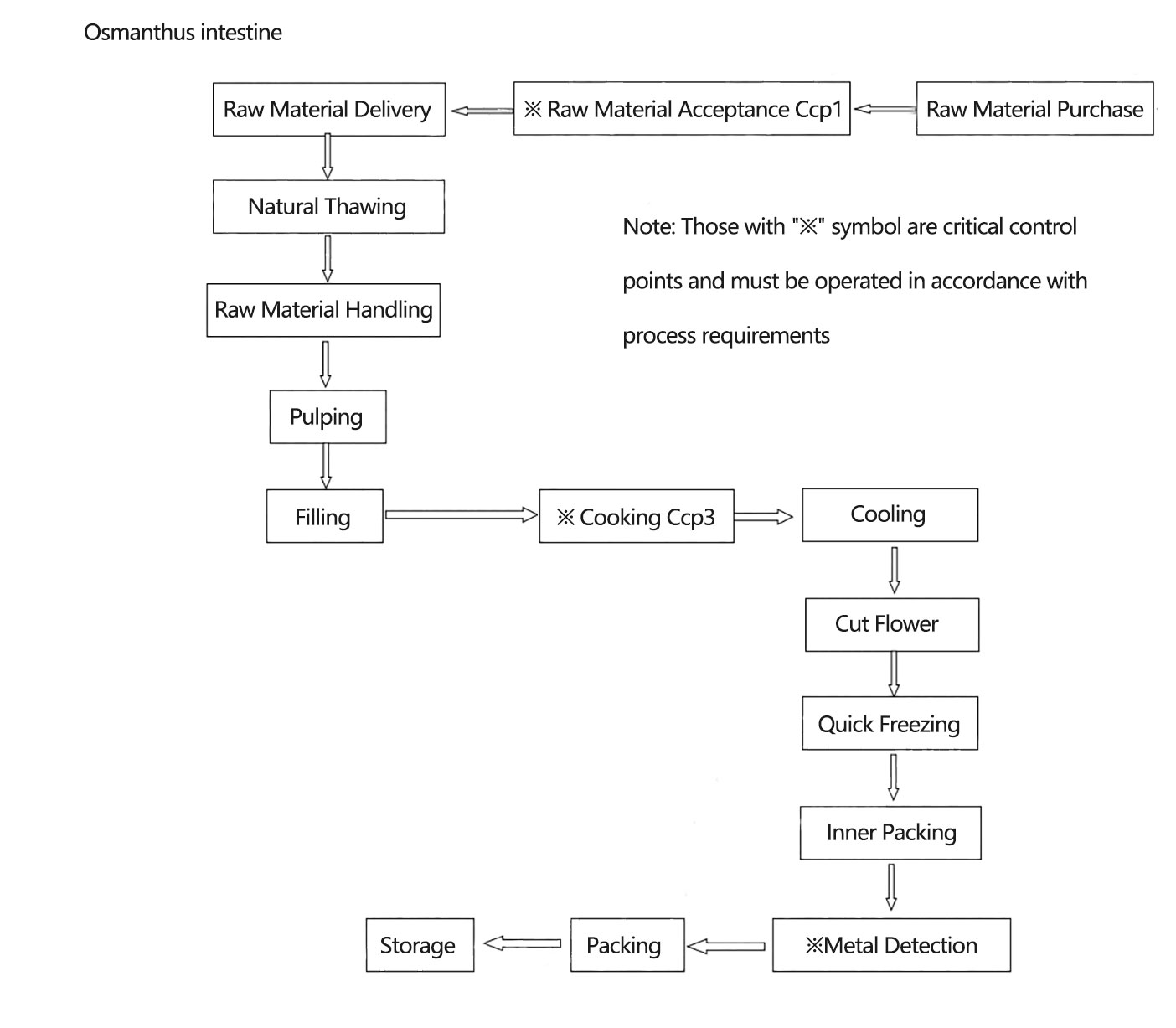

Osmanthus intestine:

1. Acceptance of raw materials: All raw auxiliary materials meet relevant national standards or corporate standards;

2. Ingredients: According to the process requirements, each ingredient must be reviewed;

3. Pre -processing: According to the process requirements, different raw materials are processed by cutting machines, meat grinders, meat placing machines, etc. to meet the specifications of process requirements in order to prepare the next process;

4. Playing: According to the process requirements, put various ingredients in batches into the pulp machine. The slurry requirements meet the process standards;

5. Filling: Pour the slurry into the vacuum filling machine and use 19#casing to fill it. The filling speed is uniform.the irrigation intestines are put into the steamer to cook.

6. Cooking: The cooking is divided into two steps. The first step is to control the temperature at 60-65 degrees (reference time 30 minutes), the second step of the cooking temperature is controlled at 80-85 degrees, the center temperature of the intestine is controlled at 75-80 at 75-80 Degree (reference time 15 minutes);

7. Cooling: cool the steamed intestines naturally, cool down to 20-25 ° C;

8. Cut the flowers: The product is cooled by the cold or natural cooling into the room temperature and cooling the intestine.

9. Freeze: Invest the forming products after forming (-30 ° C to -40 ° C 30min) quick freezing, requires the temperature of the product center in half an hour to reach -18 ° C;

10. Packaging and sealing: The frozen products are placed in the packaging bag in the packaging room in the packaging room;

11. Metal detection: After sealing, each bag of products must be performed by a metal detector, and the metal detector must be monitored three times continuously when booting or changing specifications. Each bag must be a metal detector (monitoring requirements: Fe ∮ ≤ 1.5mm Sus ∮ ≤ 2.0mm)

12. Packing: The testing genuine product is required to be inspected and possessing the "Package Performance Inspection Result Form" according to the contract requirements.

13. Refrigeration in the warehouse: stored in the finished database, the library temperature below-18 ℃ (including -18 ℃) and the temperature fluctuation ≤2 ° C.

Fish roll:

1. Acceptance of raw materials: All raw auxiliary materials meet relevant national standards or corporate standards;

2. Ingredients: According to the process requirements, each ingredient must be reviewed;

3. Pre -processing: According to the process requirements, different raw materials are processed by cutting machines, meat grinders, meat placing machines, etc. to meet the specifications of process requirements in order to prepare the next process;

4. Playing: According to the process requirements, put various ingredients in batches in batches into the pulp machine. The slurry requirements meet the process standards;

5. For molding: Add the slurry to the molding machine and shape according to the process requirements. The molding temperature must be controlled at 55-58 degrees (reference time 20-25 minutes). Essence

6. Cooking: The cooking temperature must be controlled at 90-95 degrees (reference time of 6-8 minutes), and the central temperature after boiling is ≥72 ° C (reference time 6-8 minutes).

7, cooling: cooling to room temperature;

8. Freeze: Investment products after forming are put into dual spiral quick -freezer (-30 ° C to -40 ° C 30min) quick freezing, which requires the temperature of the product center in half an hour to reach -18 ° C;

9. Packaging and sealing: The frozen products are put in the packaging bag in the packaging room in the packaging room;

10. Metal detection: After sealing, each bag of products must be performed by a metal detector, and the metal detector must be monitored three times continuously when booting or changing specifications. Each bag must be a metal detector (monitoring requirements: Fe ∮ ≤ 1.5mm Sus ∮ ≤ 2.0mm)

11. Packing: The inspection of genuine products according to the contract requirements, the packaging box required must be passed through the inspection, and has the "Package Performance Inspection Result Form".

12. Refrigeration in the warehouse: stored in the finished library, the library temperature below-18 ° C (including -18 ° C) and the temperature fluctuations ≤2 ℃